Description

Class A one-way flow hood is an air purification equipment that provides

class A one-way flow and creates a local high cleanliness environment. Its

working principle is to pass the air through the high-efficiency filter at a

certain wind speed, and then equalize the pressure through the damping layer, so

that the clean air flow is sent to the work area in a unidirectional flow, so as

to obtain the required flow pattern and cleanliness of the work protection area.

Class A unidirectional flow hood can be used singly or in combination. The

working area of the class A unidirectional flow hood is the sterile core area.

The operator needs to open the equipment from the class B background area

environment according to the defined SOP, and perform process operations and

interventions. These actions need to be formulated according to the risk to the

product. The operator should avoid contact with the sterile core, if it needs to

be contacted, it should be through isolating gloves or half-dress.

|

Model |

Dimensions(mm)(L×W×D) |

Work area size(mm)(L×W) |

Air outlet |

Work area |

Noise(dB) |

Illumination(Lx) |

Power( K W ) |

|

LUFH12-120.60* |

1200×600×600 |

1200×600 |

0.45±20% |

A |

65~75 |

300~500 |

0.3 |

|

LUFH16-100 100* |

1000×1000×600 |

1000×1000 |

0.45 |

||||

|

LUFH24-120 120* |

1200×1200×600 |

1200×1200 |

0.6 |

||||

|

LUFH32-200.100* |

2000×1000×600 |

2000×1000 |

0.9 |

||||

|

LUFH48-120.120* |

1200×1200×600 |

1200×1200 |

1.2 |

||||

|

LUFH65-200.200* |

2000×2000×600 |

2000×1000 |

1.8 |

Note:The specficationsited in the table are only for reference.Most class A

unidretional laminar Flow hoods are designed and manufactured according to URS

of customers.

HEPA ensures low resistance, high efficiency, and more reliable liquid tank sealing.

Internally and externally consistent, clean and without any dead corners.

Rich control forms to meet different customer requirements. Multiple pressure equalization, uniform wind speed, and good unidirectional flow pattern. Imported fan, high residual pressure, low noise and energy-saving, reliable performance.

The design is simple, the maintenance cost is low, and it provides an efficient A-class clean environment,. Can be used for the assembly, testing, inspection, and other production processes of sterile products that require ultra cleanliness. Integrated fan filter module with low noise.

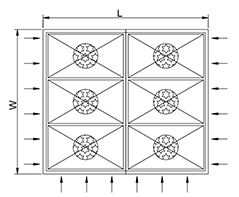

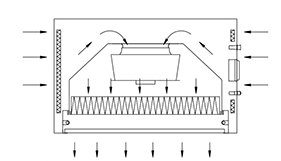

Product schematic diagram:

|

|

|

1.Outer casing 2. Inner box 3. Fan 4. Return air orifice plate 5. Plate initial effect 6. Uniformity membrane 7. DOP dust outlet 8. Differential pressure gauge 9. DOP sampling port 10. Efficient liquid tank 11. Lighting fixtures |

|

1.Outer casing 2. Inner box 3. Fan 4. Return air orifice plate 5. Plate initial effect 6. Uniformity membrane 7. DOP dust outlet 8. Differential pressure gauge 9. DOP sampling port 10. Efficient liquid tank 11. Lighting fixtures |

|

|

Reviews

There are no reviews yet.